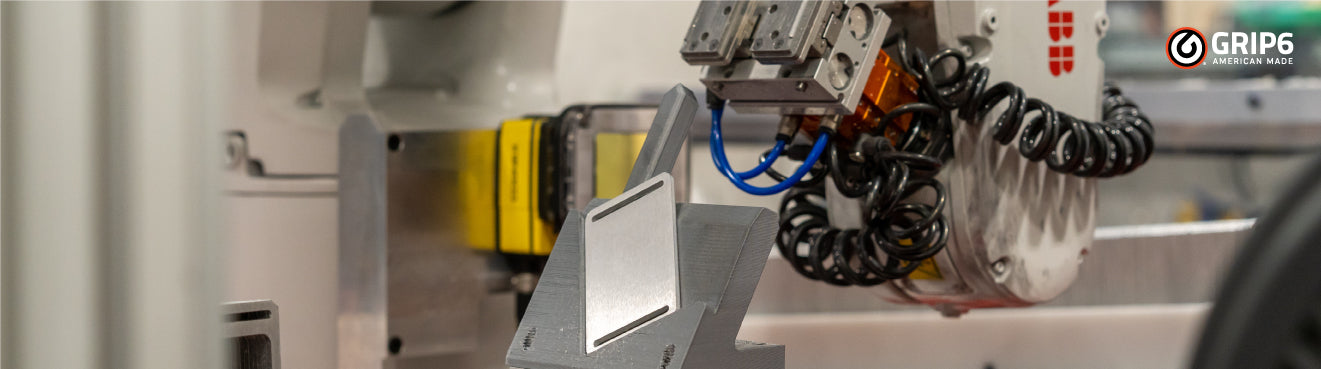

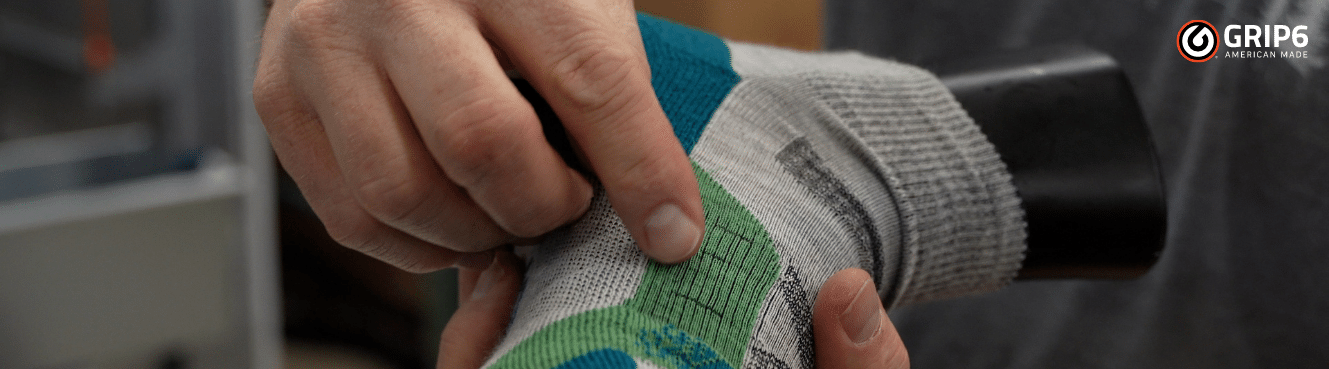

Come and see how your favorite belts are made! In this video, our engineers Amol and Jacob show the increasing importance of robots in GRIP6 Belts.

Robots have helped us automate and perfect the quality of our buckles. But robots are really only as good as the engineer who codes and develops the robot. Not only have our robots saved us significant space and time but robots have also opened up a world of creative possibilities for different designs.

Thanks and congratulations to Robert R. for your question, which is answered in the video (so watch to see)!

We enjoy reading everyone's comments and questions, so thank you for sending those in and keep them up! We look forward to making more of these videos and sharing this journey together with you.

'Till the next episode!

-GRIP6

23 comments

GERALD WIEBE

Thank You for the video about the robot used in your production. It makes one appreciate what all goes into a GRIP 6 belt.

Do you foresee a time when you might offer custom buckles, machined to a design submitted by customers? Clearly this would require a certain volume production run.

Regards, Gerald Wiebe

RC Andrews

I wonder if you sped up the robots, you might be able to keep more buckles in stock?

John Schettler

As a software engineer and product manager, it can be tricky to work out what feature to build next. What is your guy’s development cycle? How do you track and prioritize new product ideas and suggestions?

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.