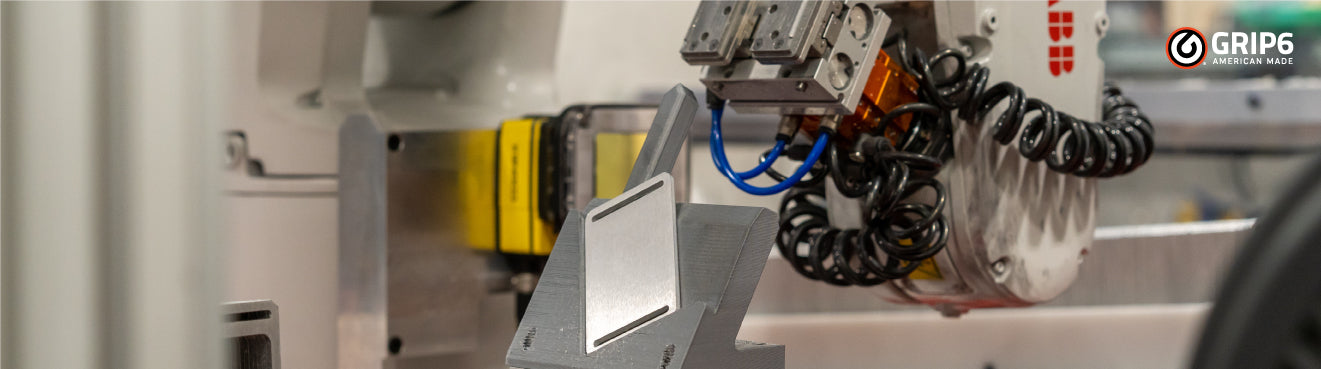

Come and see how your favorite belts are made! In this video, our engineers Amol and Jacob show the increasing importance of robots in GRIP6 Belts.

Robots have helped us automate and perfect the quality of our buckles. But robots are really only as good as the engineer who codes and develops the robot. Not only have our robots saved us significant space and time but robots have also opened up a world of creative possibilities for different designs.

Thanks and congratulations to Robert R. for your question, which is answered in the video (so watch to see)!

We enjoy reading everyone's comments and questions, so thank you for sending those in and keep them up! We look forward to making more of these videos and sharing this journey together with you.

'Till the next episode!

-GRIP6

23 comments

Nathaniel Ramirez

What is the process of getting new ideas for product?

Andrew V

Question/Answer for next video: Please share a failure and how you rectified it? Interested in learning about your path to success. Thanks. Your fellow GRIP6 fan

Scott Burrall

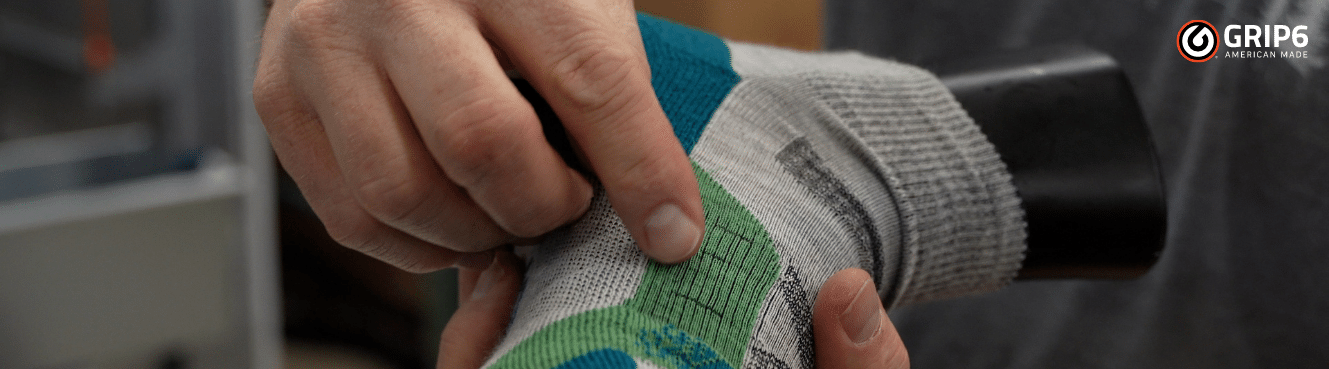

Just got my first Grip6 belts this XMas and absolutely will never buy another belt. Happy to see the American made quality in which you build your product. Would love to see how the wallets are made and where the RIFD is placed in construction of them.

Adam Altman

I love the videos. The complexity of the manufacturing and quality process is often underappreciated. Thanks for showing it to us. Looking forward to the next fortnightly installment.

I am curious. Have you delved into the color preferences and color trending patterns of your products? Are there any clear winners by gender, region, or other demographic?

Mark Cannon

Love the videos! My questions is a repeat. I applaud your decisions to source and manufacture in the USA. Have these decisions helped or hurt with the"supply chain issues" that we have seen around the country/world?

Leave a comment

All comments are moderated before being published.

This site is protected by hCaptcha and the hCaptcha Privacy Policy and Terms of Service apply.